Ensitech (Australia)

TIG Brush TBE-550

TIG Brush TBE-550

Summary

The TIG Brush Stainless Steel Weld Cleaning System utilizes a unique combination of electricity, heat, and chemistry to deliver superior results in weld cleaning and metal surface finishing

Usage: Weld Cleaning, Passivating, and Polishing of Stainless Steel

Welding Type: TIG and MIG Weld

Key Features:

- Non-Hazardous

- Extremely Fast (seconds compared to hours taken by traditional methods viz. K2 Paste)

- No Rusting or White Spots

- Corrosion Resistance

.

Description

Clean & Passivate Welds in Seconds with TIG Brush

TIG Brush stainless steel weld cleaning system is a unique combination of electricity, heat, and chemistry to deliver superior results in weld cleaning, passivation, and metal surface finishing. It is designed to rapidly remove the discolored oxides that high welding temperatures cause, without altering the look and finish of the metal.

.

Functions

.

Say Goodbye to toxic pickling paste

Easily meet OSHA standards by saying goodbye to pickling paste. Gone are the days of cleaning welds with hazardous chemicals with TIG Brush bypassing all the time-consuming frustration we’ve come to associate with cleaning stainless steel welds.

.

Prevent corrosion with passivation

Contrary to popular belief, stainless steel can corrode if it’s not treated properly after welding. The heat destroys a layer that protects it against corrosion. The TIG Brush instantly removes the hint tint and restores this layer (also called passivation).

.

.

It’s Time to Experience the Tig Brush Difference

.

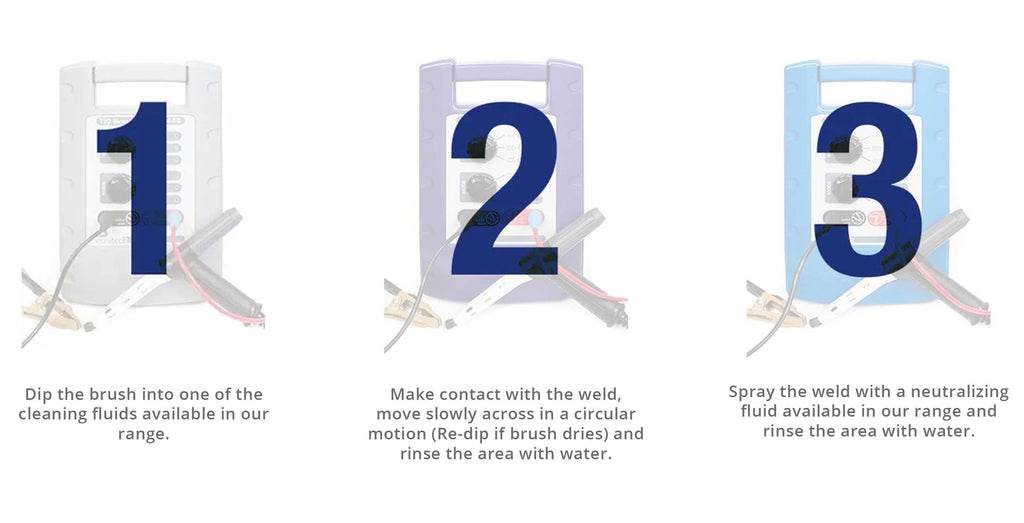

3 EASY STEPS WITH THE TIG BRUSH

The TIG Brush comprises a brush through which an electric current is passed. The brush is dipped into a cleaning fluid and then applied to the areas to be cleaned. The fluid is designed to remove the iron oxide marks which result from welding. The brush is designed to convert the electric current to high temperatures, especially at the end of the bristles. While the fluid is quite benign at room temperatures, the brush heats the fluid to an elevated temperature, when it becomes much more reactive. This results in an accelerated chemical action at the surface of the Stainless Steel.

.

.

TIG Brush Benefits

.

.

Specifications

.

.

Trusted by

.

.

Industrial Uses

|

|

|

Share